June 19, 2024

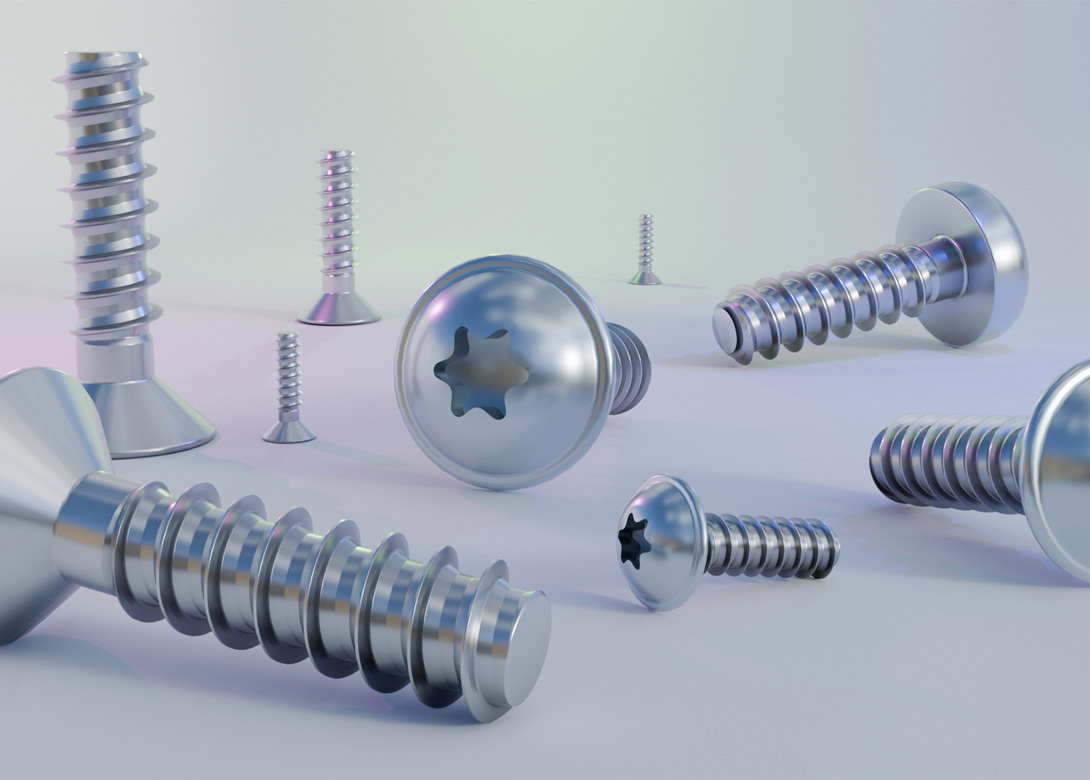

New Plastec 30-20® TR Fastenings' screws improve fastening possibilities in plastic applications in industries including automotive, technology, infrastructure and medical, providing additional benefits to TR's customers' production processes.

Plas-Tech 30-20 manufactured in TR facility® The range is developed by our global technical engineering team and features optimized thread profiles to provide advanced performance in a variety of plastic materials.

Plastic 30-20® Although the screws are new to the market, they are part of the company's established Plas-Tech product range.® This series has been specially developed to offer several advantages over traditional plastic thread forming screws. These features include a 20% finer pitch that helps reduce installation time and a lower flank angle that helps improve axial resistance.

Plas-Tech 30-20 is also available with a variety of protective coatings® The thread range features a small thread angle to help reduce axial displacement during application, a faceted thread profile directs material flow to reduce radial stress, and the threads are equipped with a large core thread profile to provide high torsional and tensile strength.

Smooth installation process for Plas-Tech 30-20® They offer increased resistance to vibration, can be installed with a calibrated air or power screwdriver, and the fasteners can be removed and reinstalled multiple times.

Plastec 30-20® Thread types include pan head, flange head and countersunk head, allowing TR customers to choose the best option for each application. Thread diameters are 3mm, 4mm, 5mm and 6mm, and lengths range from 6mm to 30mm.