Kusakura, a century-old judo uniform manufacturer, maintains its dominance in the industry with its proven technology, helping propel the Japanese-born martial art on its way to becoming an international sport.

Change with the sport

From its humble beginnings in the late 19th century, judo has transformed into an international sport. As it evolved from an obscure Japanese martial art to an Olympic sport, more and more judokas came from disciplines like wrestling and jiu-jitsu, and new techniques and strategies were incorporated. As judo grew, the emphasis remained on scoring decisive points. OneIt's a high standard that continues to attract people from all walks of life to the sport.

Japan's continuing influence on judo culture has helped maintain the sport's elegance. Century-old martial arts equipment manufacturer Kusakura has played a key role in this by helping set the standard for the judogi worn by the world's top athletes. The company supplied the Japanese national team when judo was first featured as an Olympic sport at the 1964 Tokyo Olympics.

From left: Kusakura's original shop, with an early display of judo and other martial arts equipment and uniforms. (Courtesy of Kusakura)

The uniform worn by Jigoro Kano, the founder of judo, is on display in the lobby of Kusakura's headquarters. (© Kumazaki Takashi)

Kusakura was founded in Kashiwara, Osaka Prefecture, in 1918. Masahiko Miura, the sixth-generation president, says the company was born out of the region's long tradition of weaving, which dates back to early modern times. When Miura's grandfather began making judogi, he was looking for specially woven Sashiko weaving The fabric is made from locally produced Kawachi cotton.

Sashiko weaving It is a traditional weaving technique that reinforces the fabric by stitching the threads together, making it warm and durable. Along with its practical function, it also developed as a decorative technique for decorating textiles. Miura's grandfather was the first person to recognize the strength of thread. Sashiko weaving Judo uniforms need to be durable enough to withstand the rigorous demands of the sport, and this fabric is still the standard used today.

As Kusakura grew, they began to sell uniforms and equipment for other martial arts and even weaved their own fabrics. Shortly after the war, under the occupation of Japan, demand dropped when GHQ banned martial arts training in schools. To survive, Kusakura turned to making work trousers. However, once the ban was lifted, Kusakura quickly resumed making judogi and expanded their business.

Since then, we have been working to improve the quality of judo uniforms with a commitment to manufacturing, such as developing the industry's first bleached fabric and succeeding in fully mechanizing the weaving process. We have also contributed to the spread of blue judo uniforms.

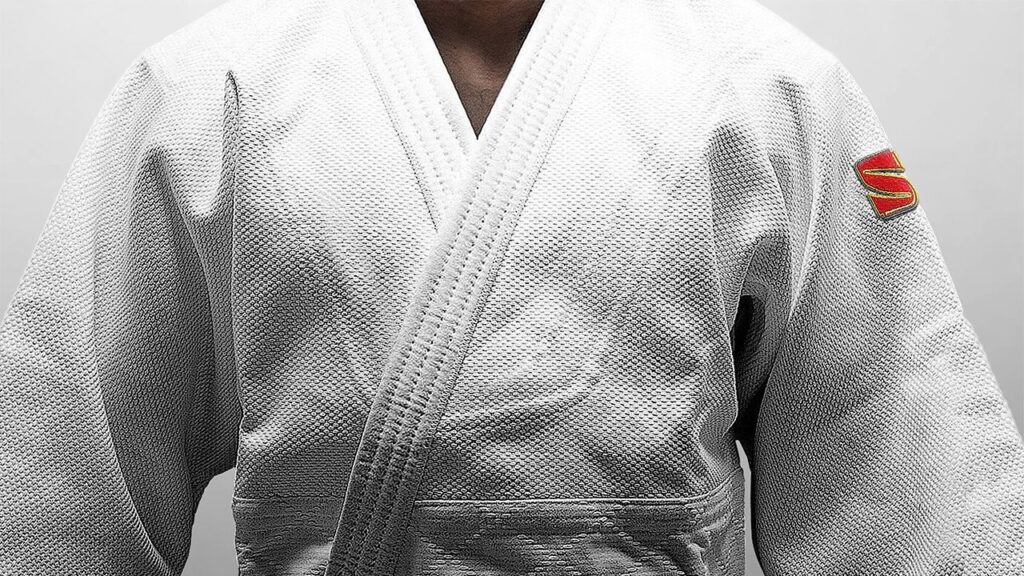

Kusakura's uniforms sell for around 30,000 yen and are certified by both Japanese and international judo governing bodies. (Courtesy of Kusakura)

Establishing competitive standards

For most of judo's history, there were few regulations regarding uniforms. As the level of judo increased, passive strategies began to emerge in major international competitions to bring matches to a decision. To aid in this, some participants began to wear jackets with stiff collars and narrow sleeves that prevented their opponent from getting a firm grip, making a decisive score less likely. One The costumes are cheap and of inferior quality to those made in Japan, raising concerns that their widespread use could fundamentally change judo.

In response, the International Judo Federation moved in 2014 to establish clear rules regarding uniforms to ensure the fairness and integrity of matches. Miura says the IJF consulted with Kusakura on the changes and modelled its uniforms on them. The company continues in an advisory role. “We've been involved with every Olympics and in subsequent revisions,” Miura explains.

New regulations set specifications such as how wide the collar should be when folded, ensuring the fabric was not too stiff, and the weight and strength of the material per square meter. The heavy 100% cotton fabric normally used was replaced with a 70% cotton/30% polyester blend to make the uniform lighter without compromising its strength.

Each and every Kusakura uniform is carefully hand-sewn. (© Takashi Kumazaki)

There are currently 15 IJF certified sportswear manufacturers. While Kusakura's production volume is modest compared to the larger manufacturers on the list, which includes many international brands, the company boasts a strong reputation due to its long history as a specialist judogi manufacturer.

Many companies outsource production overseas, and Kukura also outsources its judo uniforms for school athletics. However, when it comes to judo uniforms for competitions, Kukura produces them entirely in-house. “We are the only company in the world that does everything in-house, from weaving the fabric to the final stitching,” Miura asserts.

High Quality Craftsmanship

Judogi manufacturing is complex and involves many steps. The investment and expertise required is a barrier to entry for niche markets and the reason why many companies outsource production overseas. In this respect, Kusakura's long history works in its favour. “People think of judogi as being stiff and bulky,” explains Miura. “But we control the quality by weaving the fabric ourselves, and produce clothes that are light and comfortable to wear.” From cutting to sewing, every step is done by hand by skilled craftsmen, and with feedback from customers, they achieve a custom-made feel.

Miura acknowledges that Kusakura faces challenges from rising material costs and an aging craftsmanship. “Young people don't want to enter the textile industry,” he laments. “We have training programs to pass on the techniques and know-how that have been cultivated over generations, but it's an uphill battle.” He notes that the company's concerns also extend to aging machinery. For example, the looms the company relies on to weave its fabrics are no longer in production, and replacement parts are in short supply. “When something breaks, an operator has to make a replacement by hand.”

Despite these challenges, Kusakura has maintained an unwavering commitment to quality, and while their products may be more expensive than many on the market, their excellence has made them the choice of top judokas.

Masahiko Miura at the Kusakura factory. (©Kumazaki Takashi)

Many of the big sportswear brands have contracts with judo federations to supply uniforms for major tournaments, meaning athletes from many countries have to wear sponsored clothing. This puts smaller companies like Kusakura at a disadvantage, but Miura is adamant that the company will not be intimidated by its larger rivals. “At the 2014 Rio de Janeiro Games, 11 of the 56 medallists wore our uniforms,” Miura asserts. “We tied for second place, which shows that we may be small, but we can compete with the big brands.”

Kusakura has focused on the domestic Japanese market, but with the declining population, they are looking to expand their share overseas. “In 2013, we traveled to the World Championships in Brazil to promote our judo wear. We met with federation officials from each country and visited dojos in Rio and Sao Paulo,” explains Miura. It took time to raise awareness, but their tenacity paid off, leading to a contract with the Brazilian national team in 2022. “Brazil has a large Japanese population and has grown into a judo powerhouse on a par with France. It is said to have the largest judo population in the world.”

Kusakura strives to build a strong reputation within the world of judo and with 100 years of experience and an ongoing commitment to quality, it is well positioned to lead the development and evolution of judo.

(Banner photo: Kusakura's hand-sewn judo uniforms. Courtesy of Kusakura.)