Any owner who drives a vintage car is aware of the gap between old-fashioned manufacturing techniques and the quality of modern vehicle assembly. I've owned cars designed in the '60s, '70s and '80s, and there's little doubt that even the most poorly designed and manufactured cars today exceed the standards of decades ago. And I'm not talking about serious issues that will have you stranded on the side of the road cursing your luck as your prized possession slowly rides up onto a flatbed. No, I'm talking about the many manufacturing inconsistencies, high tolerances, “just-so” part designs and lax attitude toward planned obsolescence that were built into much of pre-1990s auto manufacturing.

It's easy to overlook some of these issues during the honeymoon period when owning a classic car and every mile feels magical, but in the long run, unreliable switches, shaky wiring, tricky fuses and fiddly mechanisms will inevitably pop up and you'll learn in detail exactly what was neglected during the car's development, either for lack of investment or simply for quality control reasons.

All of this adds up and becomes a pain when you have to make a simple repair for the third or fourth time in the middle of a driving season. Throwing the same OEM part at the problem only to fall victim to its own inability to function to the specs you envisioned decades ago, only for the universe to rip it apart and spit it back out a month or two later, feels like Sisyphus's penance.

That's exactly the situation I found myself in with my 1987 Jeep Grand Wagoneer, a car built during the transition between AMC and Chrysler, two companies notorious for their lack of commitment to quality at the time. After years of plagued by a defective window that prevented me from fully enjoying the car, I unexpectedly got the chance to start over with an upgraded replacement part.

The problem? It was hideously expensive, at least compared to sticking with the factory setup. Here, I was forced to ask myself a question that is probably familiar to the majority of classic car mechanics: Buy it once and never cry again, or roll the dice and risk dying for pennies?

Flex track? Similar to “Break That”

Allow me to introduce you to my nemesis, the Jeep Flex-Trac window system, a feature that I can only assume is the product of a frantic cost-cutting spree by AMC executives trying to offer a premium power window experience as cheaply as possible in the brand's flagship full-size SUV.

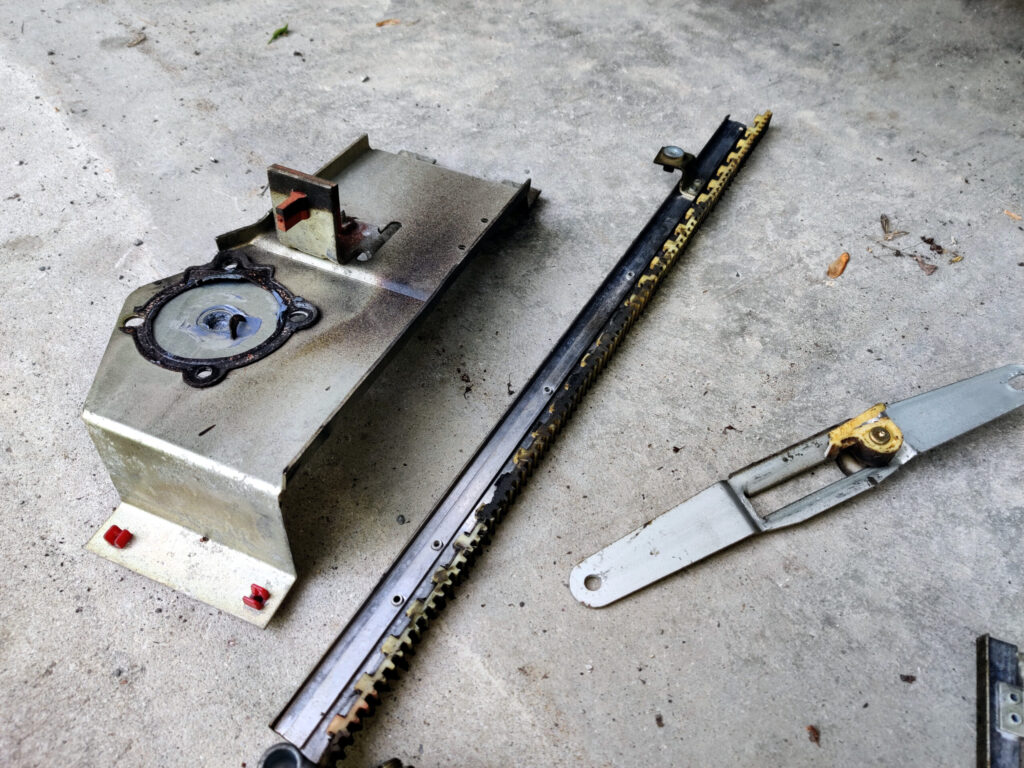

That doesn't sound like luxury. Rather, the flex-track is a panic-inducing piece of plastic with the torsional strength of overcooked pasta. Each of my Waggy's four doors has a built-in setup. As designed, this PVC strip moves up and down a J-shaped metal rung, via segmented teeth that run through a motor at the bottom of the door. At the top, the flex-track forms a single turkey-neck-like contact point with the window itself, supporting the full weight of the glass on its bulging head, though I highly doubt it would survive more than a dozen ups and downs.

As far as I can tell, the Flex-Trac seems like it was born to break. Teeth break, motor gears slip, and top mounts break with alarming regularity, causing windows to slide down into doors. The resulting gaps provide an attractive invitation for both thieves and the elements. Chrysler made a sturdier metal version of the Flex-Trac, but it was only offered for one model year and was never sold as a replacement part, meaning you're more likely to find one at a craps table in Las Vegas than at your local junkyard.

Since purchasing my Grand Wagoneer in 2019, I have replaced the flex tracks at least two or three times each year. This task initially required opening each door and removing the entire mechanism. I have now become so adept at the job that I can install the flex tracks completely unobtrusively on the inside of the front doors, with the motors still firmly attached. The only bright spot in this storm of failure is that flex tracks are not expensive, costing up to $20 on average, depending on which supplier you choose. I keep a steady stock of tracks in my garage ready to be installed at any time.

But that's not the crux of the issue. The real damage done by the Jeep Flex-Trac debacle is the mental stress of not knowing if the part currently on the inside of your door will finally work the next time you flick the window switch. It's pretty frustrating to pull into a drive-thru in a rainstorm, grab a snack, and hear the gears click into place. Or, even worse, slide into a parking space, hit the “up” position, and realize your truck is broken. Is it time to get out your tool kit, peel back an interior panel, and manually push the glass up? Maybe it's better not to go home and risk a break-in.

Lest you think I'm exaggerating when I say that my FlexTrac breaks down frequently, I began traveling with a stack of rubber wedges in my glove box so I could slip them between the glass and frame in case of an accident before the windows were fully hidden inside the doors. Every trip became a gamble as to whether all four windows would work by the time I got home, and I slowly but surely began to hesitate every time I reached for the Jeep keys to go to the door.

Big Buck Solution

The turning point for me came this spring, when, as I was parking in the garage after my first drive of the year, the Grand Wagoneer's driver's window moved in its usual nonsensical way. The engine roared helplessly inside the door, and the glass remained determinedly ajar. I shut it off with a curse and dug out my spare Flex-Track, which had been buried in the attic under the debris of our recent move to the country.

That same evening, I stumbled across a post in my Jeep Facebook group. It was an incredible story: BJ's Off-Road, the country's most trusted source of full-size Jeep-related parts and the company I turned to when I traded in my own car for an LS, had announced the production of a complete power window conversion kit for all Wagoneers made between 1963 and 1991. Replacing both the existing power windows and the old manual setup, the kit permanently eliminated the flex-track in favor of a simple, reliable mechanical arm design.

The timing was perfect, and the sales pitch was irresistible. There was just one problem: the price. With a list price of $1,250, plus shipping, import duties, and taxes, the entire kit and associated hardware came to just under $2,000 (the unofficial currency in Canada, where I live). That means I'd be spending $500 per window to avoid the mental turmoil and constant hassle of having to replace $20 flex tracks one after the other.

At the risk of your life

And did I still make that choice? Given the history of my financial decisions regarding Grand Wagoneer ownership, you won't be surprised to learn that I did, and I don't regret my decision at all.

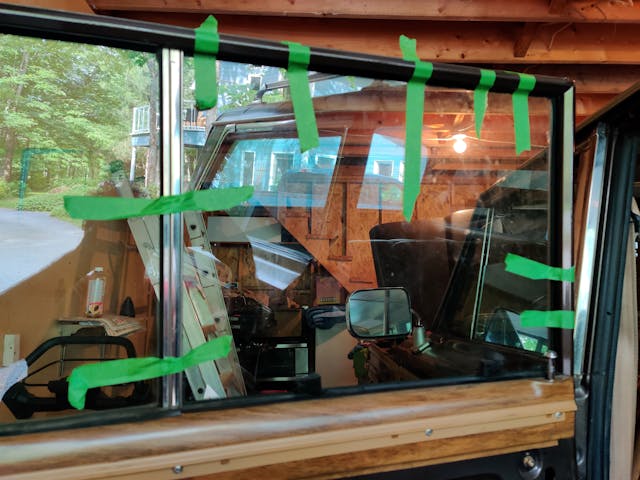

The kit came with very few installation instructions, but the folks at BJ's were always there to answer questions and walk me through the steps when I got stuck. The only issue I ran into was that three of the four motors were actually wired backwards (with bottom being “up” and vice versa), which seems to be a common occurrence when dealing with aftermarket power windows. The kit did come with instructions on how to reverse the polarity of the motors using the pigtail connectors that came with the wiring harness, which was relatively easy to accomplish.

I am very happy with the end result, I also took the opportunity to install a relay kit I had lying around on the shelf, giving the new motor more power than my Jeep's 35 year old switch could provide, and the motor is now making quick work of lifting jobs.

It actually has some effect Too Yes indeed. The longer travel distance provided by the mechanical arm design causes the windshield to go too far into the door and contact the locking mechanism. This must be solved with a window stopper taken from a manual window model. As with most older machines, installing newer, stronger parts also revealed the limitations of the existing framework around it. In particular, my rear window guide seems to be warped enough that the window would get stuck if it was rolled too far into the door. Not surprising for a Grand Wagoneer that has never been known for stellar build quality.

The reality of the classic car world is that completely solving a problem can cost as much as 25 times what you would normally expect. Everyone must draw the line for themselves as to whether they are comfortable spending a lot of money on a solution that approaches the reliability of a modern car. It's a personal decision. Sometimes, at this point in the car's life, you just have to accept the fact that there are aspects of owning an old car that will never perform to spec.

Ask any owner of an E36-generation BMW 3 Series (or Z3) how much they spent to replace a weak plastic part in their cooling system. Or ask a '60s muscle car owner how much they spent to upgrade to an electronic ignition system. Or ask a Range Rover enthusiast how much they've spent on pretty much everything. The answer from an enthusiast is almost always the same: if there's a better way to get the job done, it's worth the extra investment to get the job done right.

Sure, power windows may not seem on the same level as engine cooling or timing, but the net effect is the same. The FlexTrac issues had me locked in a prison of anxiety and made it impossible to trust my Jeep as a daily driver. Any problem that turns your Jeep from a beloved road trip companion into a garage ornament should be at the top of your list of things to fix. This power window kit was certainly costly, but it gave me a chance to enjoy driving again the way I wanted to. And isn't that the point?

***

Be sure to check out the Hagerty Media homepage so you don't miss a thing. BookmarkSubscribe to our newsletter to get the best articles delivered straight to your inbox..