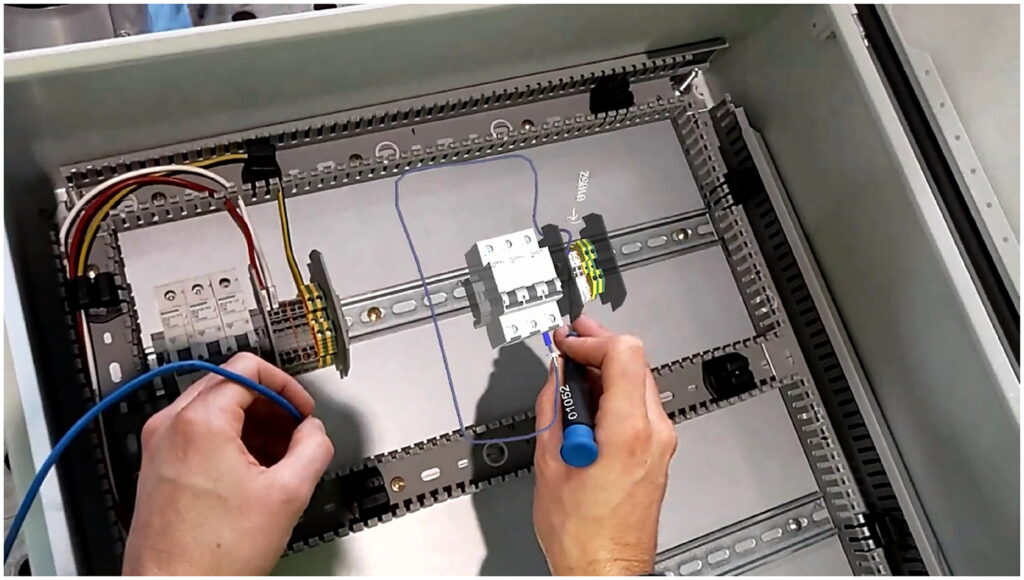

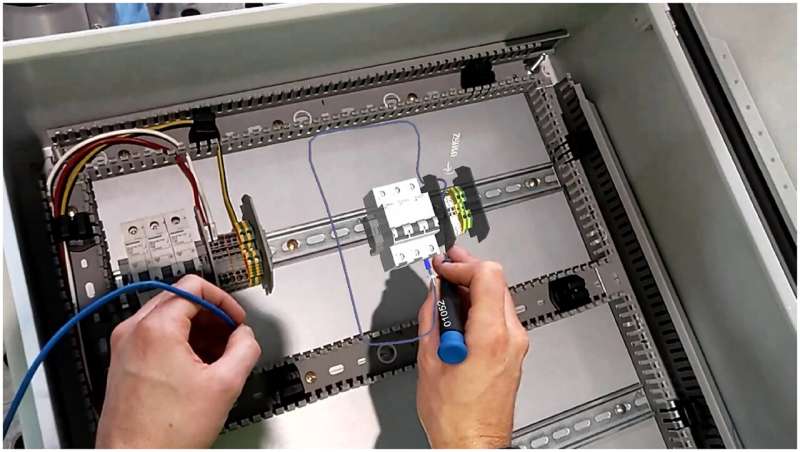

View from Hololens AR HMD: A worker uses a reference hologram to assemble wiring inside an electrical cabinet. Electrical cabinet with terminals. Worker uses two hands to manipulate tools to attach wires to terminals. A 3D hologram appears to the right of the terminal to show correct position of wire. Credits: Ergonomics (2024). DOI: 10.1080/00140139.2024.2352733

High-tech factory workers of the future will rely on training and support in Industry 4.0 technologies such as augmented reality head-mounted display modules (AR-HMDs) to manage workflows and remote troubleshooting, according to Flinders University experts. This will also be true for next-generation shipbuilding.

According to a new article published in the journal Neuroscience, trials of AR-HMD technology that could improve productivity by reducing and correcting errors in advanced manufacturing and assembly will improve software, tracking, and other promising features. Ergonomics.

“Despite a push for the adoption of Industry 4.0 technologies to stimulate flexibility and competitiveness in manufacturing, adoption has been slow in Australia,” said Dr Valerie O'Keeffe, senior research fellow in human factors at Flinders University and first author.

“The Royal Australian Navy Hunter-class frigate program provides an opportunity to accelerate technology adoption to improve productivity and workforce skills in a traditional, complex and critical industry.”

“Augmented reality head-mounted displays can be used to provide digital information directly to users and guide them in completing work tasks.”

To understand the shipbuilder's user experience and workload, the research case study focused on the “AR-HMD Hololens 2” in a simulated manufacturing workflow, which involves multiple tasks (electrical assembly, inspection, and quality assurance) performed by a collaborative robot equipped with a visual inspection camera.

The study was carried out at Osborne Naval Shipyard with support from industry partner BAE Systems Maritime Australia.

Dr O'Keefe said this research highlights AR-HMDs as a potential means to integrate advanced technologies and improve functionality while minimizing burden on the end user.

“This will be beneficial to speed up learning and increase skill levels in a workforce that is facing a shortage of skilled workers,” she said.

“Interface design, tracking, gestures, and device durability are likely to limit the adoption of AR-HMDs and improvements are needed to ensure efficient deployment in operations.

“However, our findings suggest that employee acceptance of and motivation levels of technology may increase, promoting learning and productivity.

“The findings will help with technology adoption and the knowledge can be applied to other heavy industries outside shipbuilding.”

For more information:

Valerie O'Keefe et al. “Perspective-Making: An Ergonomic Case Study of Augmented Reality Collaboration in Assembly” Ergonomics (2024). DOI: 10.1080/00140139.2024.2352733

Provided by Flinders University

Quote: Augmented reality technology boosts manufacturing productivity (July 1, 2024) Retrieved July 1, 2024 from https://techxplore.com/news/2024-07-augmented-reality-tech-aids-productivity.html

This document is subject to copyright. It may not be reproduced without written permission, except for fair dealing for the purposes of personal study or research. The content is provided for informational purposes only.